Nimonic 90/UNS N07090

| Cov hlau nplaum | lub ntsiab lus | C | Si | Mn | S | Ni | Cr | Al | Ti | Fe | Cu | B | Pb | Zr |

| Nimonic 90 | Tsawg kawg | 18.0 | 1.0 | 2.0 | ||||||||||

| Qhov siab tshaj plaws | 0.13 | 1.0 | 1.0 | 0.015 | Qhov Nyiaj Tshuav | 21.0 | 2.0 | 3.0 | 1.5 | 0.2 | 0.02 | 0.015 | 0.15 |

| Aolly Status | Lub zog tensile RmMpa Min | Lub zog tawm los RP 0. 2Mpa Min | Kev ntev A5 Tsawg kawg% |

| Skev daws teeb meem &nag los | 1175 | 752 | 30 |

| Qhov Ceevg/cm23 | Melting Point℃ |

| 8.18 | 1310~1370 |

Qws, Bar, Hlau thiab Forging Tshuag- BS HR2, HR501, HR502 thiab HR503; SAE AMS 5829

Phaj, Ntawv thiab Sawb -BS HR202, AECMA PrEN 2298.

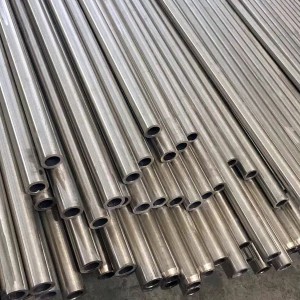

Yeeb nkab thiab tuebe-BS HR402

Sau koj cov lus ntawm no thiab xa tuaj rau peb