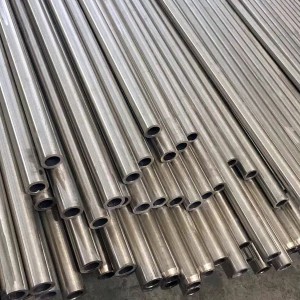

Nickel Alloy 20 (UNS N08020) /DIN2.4660

| Cov hlau nplaum | lub ntsiab lus | C | Si | Mn | S | P | Ni | Cr | Nb+Ti | Fe | Cu | Mo |

| Cov hlau nplaum 20 | Tsawg kawg |

|

|

|

|

| 32.0 | 19.0 | 8 * C |

| 3.0 | 2.0 |

| Qhov siab tshaj plaws | 0.07 | 1.0 | 2.0 | 0.035 | 0.045 | 38.0 | 21.0 | 1.0 | qhov nyiaj tshuav | 4.0 | 3.0 |

| Aolly Status | Lub zog tensile Rm Mpa Min. | Lub zog tawm los RP 0. 2 Mpa Tsawg kawg | Kev ntev A 5 tsawg kawg nkaus % |

| Annealed | 620 | 300 | 40 |

| Qhov Ceevg/cm23 |

| 8.08 |

Qws, Bar, Hlau thiab Forging Tshuag- ASTM B 462 ASTM B 472, ASTM B 473, ASME SB 472, ASME SB 473,

Phaj, Ntawv thiab Sawb- ASTM A 240, ASTM A 480, ASTM B 463, ASTM B 906, ASME SA 240,

Yeeb Nkab thiab Raj- ASTM B 729, ASTM B 829, ASTM B 468, ASTM B 751, ASTM B 464, ASTM B 775, ASTM B 474,

Lwm yam- ASTM B 366, ASTM B 462, ASTM B 471, ASTM B 475, ASME SB 366, ASME SB-462, ASME SB

Kev tiv thaiv corrosion zoo heev rau sulfuric acid

Zoo heev tsis kam rau chloride kev ntxhov siab corrosion cracking

Cov khoom siv kho tshuab zoo heev thiab kev tsim khoom

Tsawg kawg nkaus carbide nag lossis daus thaum lub sijhawm vuam

Zoo heev hauv kev tiv taus corrosion rau kub sulfuric acids