Nickel 200/Nickel201/ UNS N02200

| Cov hlau nplaum | lub ntsiab lus | Si | Mn | S | Ni | Fe | Cu |

| Nickel 200 | Tsawg kawg | ||||||

| Qhov siab tshaj plaws | 0.35 | 0.35 | 0.01 | 99.0 | 0.4 | 0.25 | |

| Lus Cim | Nickel 201 C element yog 0.02, lwm yam khoom sib xws nrog Nickel 200 | ||||||

| Aolly Status | Lub zog tensile Rm Min Mpa | Lub zog tawm los RP 0. 2 feeb Mpa | Kev ntev 5 feeb % |

| ua kom sov | 380 | 105 | 40 |

| Qhov Ceevg/cm23 | Melting Point℃ |

| 8.89 | 1435~1446 |

Qws, Bar, Hlau thiab Forging Tshuag- ASTM B 160/ ASME SB 160

Phaj, Ntawv thiab Sawb -ASTM B 162/ ASME SB 162,

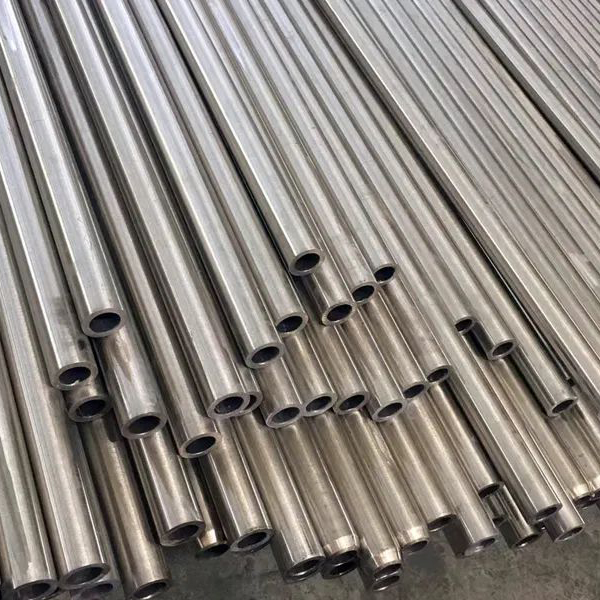

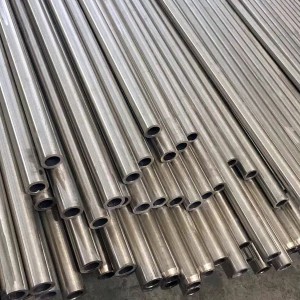

Yeeb Nkab & Raj- ASTM B 161/ ASME SB161, B 163/ SB 163, B 725/ SB 725, B730/ SB 730, B 751/ SB 751, B775/ SB 775, B 829/ SB 829

Cov khoom siv- ASTM B 366/ ASME SB 366

● Tiv taus ntau yam tshuaj txo qis

● Kev tiv taus zoo heev rau cov alkalies caustic

● Kev ua hluav taws xob siab

● Tiv thaiv xeb zoo heev rau cov dej distilled thiab cov dej ntuj

● Tiv taus cov kua ntsev nruab nrab thiab alkaline

● Zoo heev tiv taus cov fluorine qhuav

● Siv dav los tswj cov caustic soda

● Cov khoom zoo thermal, electrical thiab magnetostrictive

● Muaj qee qhov kev tiv taus cov hydrochloric thiab sulfuric acids ntawm qhov kub thiab txias me ntsis