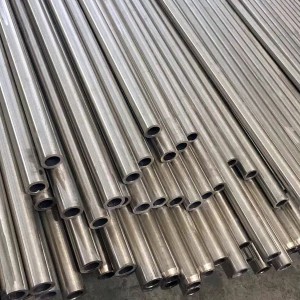

Kovar/UNS K94610

| Cov hlau nplaum | lub ntsiab lus | C | Si | Mn | S | P | Ni | Fe | Co | Mo |

| Kovar | Tsawg kawg |

|

|

|

|

| 28.5 |

| 16.8 |

|

| Qhov siab tshaj plaws | 0.03 | 0.3 | 0.5 | 0.02 | 0.02 | 29.5 | qhov nyiaj tshuav | 17.8 | 0.2 |

| Aolly Status | Qhov Nruab Nrab Linear Coefficient(10-6/°C) | ||||

| 20 ~ 200℃ | 20 ~ 300℃ | 20 ~ 400℃ | 20 ~ 500℃ | 20 ~ 600℃ | |

| ua kom sov | 5.9 | 5.3 | 5.1 | 6.2 | 7.8 |

| Qhov Ceevg/cm23 | Melting Point℃ |

| 8.16 | 1450 xyoo |

Qws, Bar, Hlau thiab Forging Tshuag- ASTM F15

Phaj, Ntawv thiab Sawb -SAE AMS 7728

Sau koj cov lus ntawm no thiab xa tuaj rau peb